Innovation Driven, Sustainability Focused

The core of our technology lies in the disruptive

innovation in multiple areas.

Advanced Membrane Materials

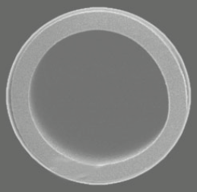

Manufactured and assembled in Singapore, our CLARITY™ membranes are made from our patented nanocomposite material, a non-toxic and non-leaching material with superior tensile strength, and strong chemical resistance.

Proprietary System Design

Leveraging on our exclusive engineering design and process control regimes, our membrane systems operate at a sustained performance efficiency, with low energy requirements.

Environmentally Sustainable Manufacturing Processes

Our membranes are produced through a solvent-free manufacturing process, eliminating the generation of any toxic wastewater that require treatment and disposal.

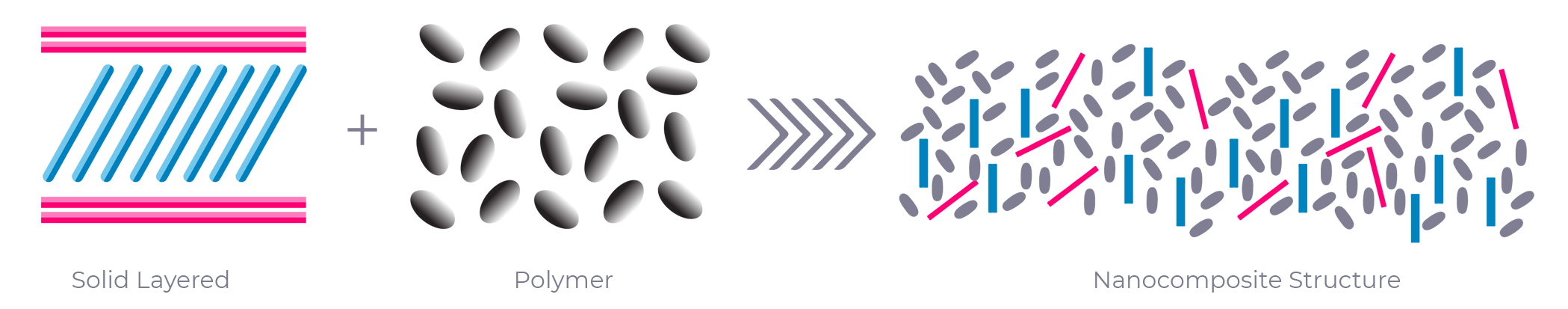

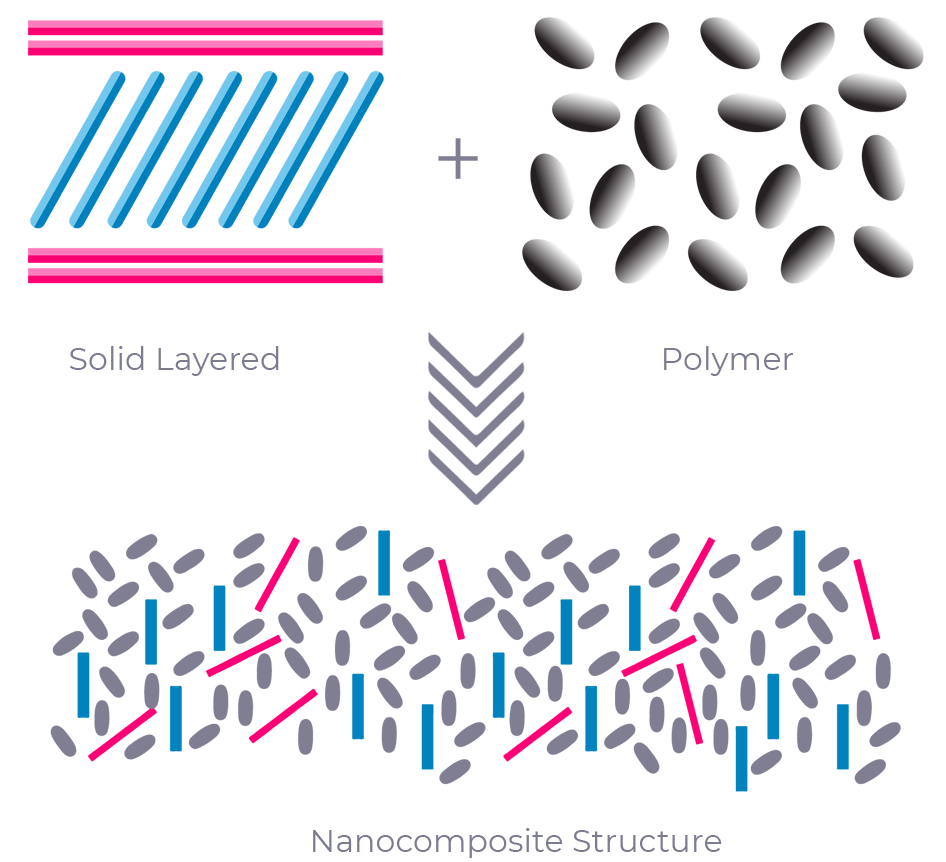

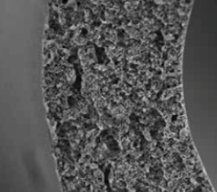

New-Gen High Strength Nanocomposite Material

Utilizing highly reliable polyolefin materials, our membrane matrix are embedded with high strength nanoparticles, providing significant reinforcement to the membrane structure.

The superior properties of nanoparticles can be transferred to the membranes, enhancing a wide range of mechanical and filtration properties such as mechanical strength and permeability.

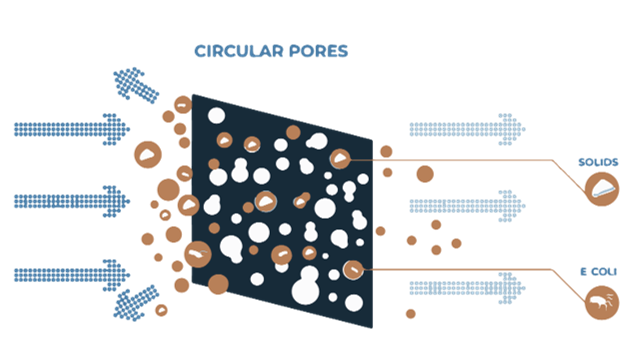

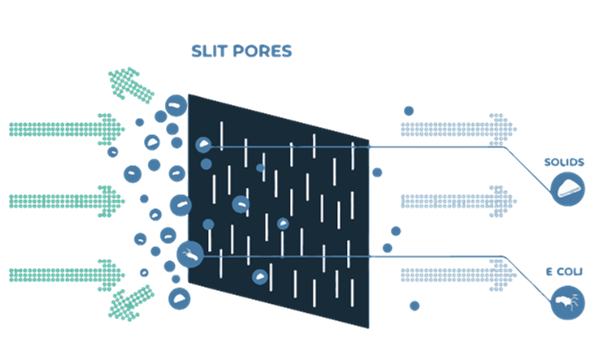

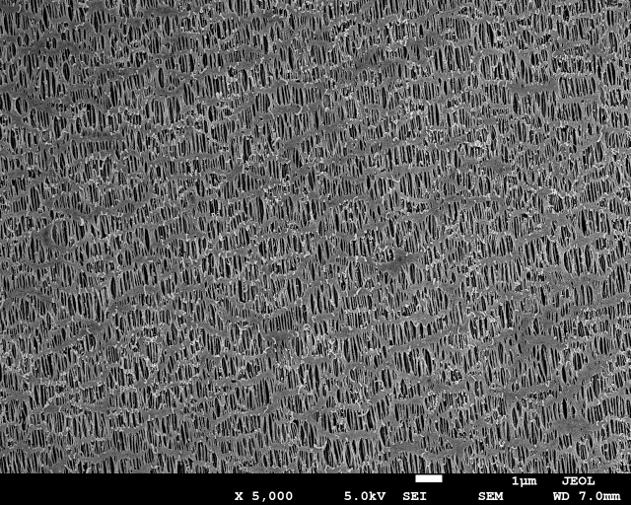

Unique Asymmetrical Slit Membrane Pores

Unlike circular pores in conventional membranes, typically created by a solvent based process, our unique melt-stretching method create asymmetric slit pore structures with a narrow pore size distribution.

These slit pores in our membranes allow better rejection of contaminants, lower fouling and excellent permeability.

With asymmetric slit pore size of <0.2um, our membranes can remove 99.99% of solids and microorganisms to produce clean water at reduced operational costs.

SURFACE

MORPHOLOGY

CROSS SECTION

With a superior nanocomposite material, CLARITY membranes have these benefits:

High tensile strength and resistance to breakage during operation

High chemical resistance to a wide range of wastewater contaminants

Large filtration surface area for higher throughput for equivalent footprint

Sustainable Production Processes

Our unique melt-stretching manufacturing process is solvent free and does not produce any toxic chemicals that pose risk to our environment when discharged without substantial treatment.

With 100% recyclable raw materials and a green production process, we are committed to providing environmentally sustainable filtration technologies.

For every water plant of capacity 100,000m3/day, CLARITY™ can help to reduce 10,000 tons of CO2 produced per year from the production of conventional membranes